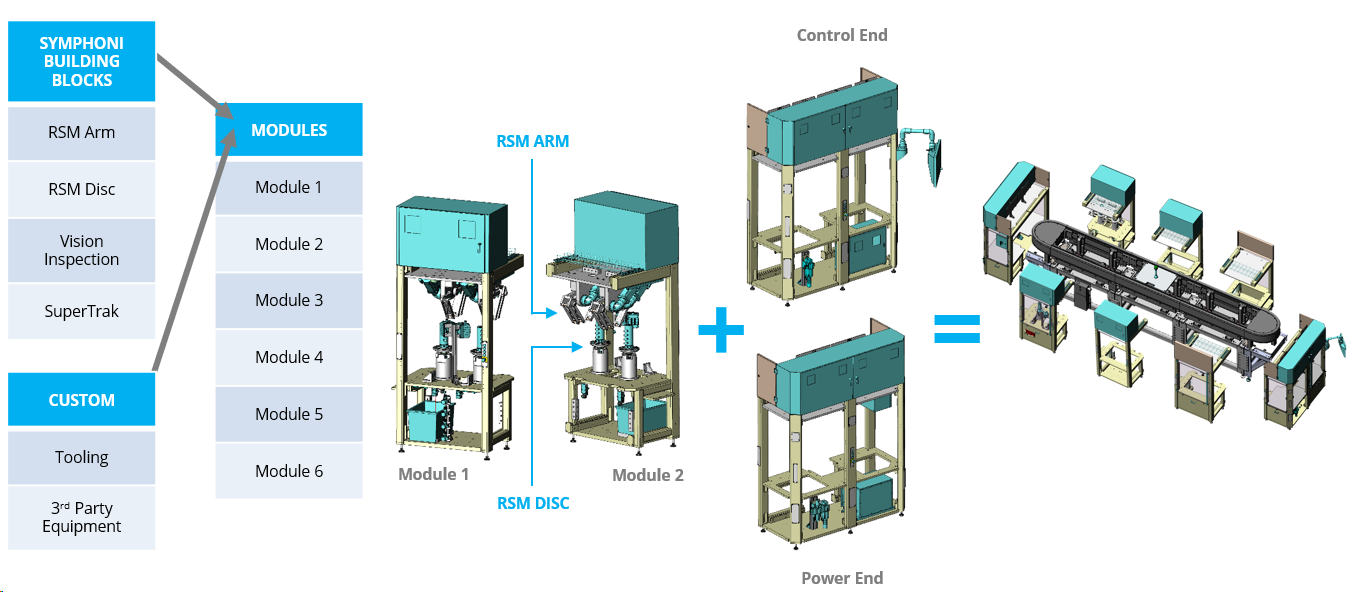

Leverage standard design platform inventory. Up to 80% of SYMPHONI™ machines are pre-configured with standardized and proven building blocks. Customize with your touch tooling and machine operation sequencing.

SYMPHONI is a versatile assembly machine that can be easily configured for multiple products. A single system can run multiple product lines with enhanced servo-based motions and digital cams with minimal retooling.

Run SYMPHONI 24/7 to maximize machine utility and consolidate slower assembly equipment to minimize floor space.

The rapid reconfiguration feature allows you to retool SYMPHONI to meet market demand.

SYMPHONI machines are configured from pre-tested and pre-validated building blocks including RSM Discs, RSM Arms, Power End, and Control End Modules.

ATS made the strategic decision to build SYMPHONI cells for inventory in 2021.

SYMPHONI’s high standardization and ATS’ investment to build its inventory has allowed us to get ahead of global supply chain issues.

Pick Your RSM

Disc

Pick Your RSM

Arm Deck

Pick Your RSM

Arm Digital Profile

Design Custom

Contact Tooling

A key SYMPHONI advantage is that there is no basic hardware design specific to a project. All control panels mounted to the Modules, Power End, and Control End Modules are identical and pulled from inventory.

This design has been tested and refined over many SYMPHONI machines. The base modules have built-in standard I/O points allotted for any additional process devices required.

Software control engineers will configure the software control by selecting from pre-tested and market-proven software apps for the assembly of a project. There is no custom PLC program for the SYMPHONI cell. Furthermore, the feeders supplying parts to the cell are simplified because SYMPHONI’s RSM Arm and standard end-of-arm tools do the part orientation.

ATS does not depend on third-party feeder companies to handle the challenges of pre-inspection and parts orientation.

The software control Engineers will custom code the remaining cells. These cells have more traditional automation components such as the mold unload, puck triage zone and ATS-designed tray handler. The SYMPHONI cell has standard approaches to load and unload, reducing the risk of integrating the cell into a larger system.

Tell me more

Find out how the SYMPHONI assembly platform can work for your application