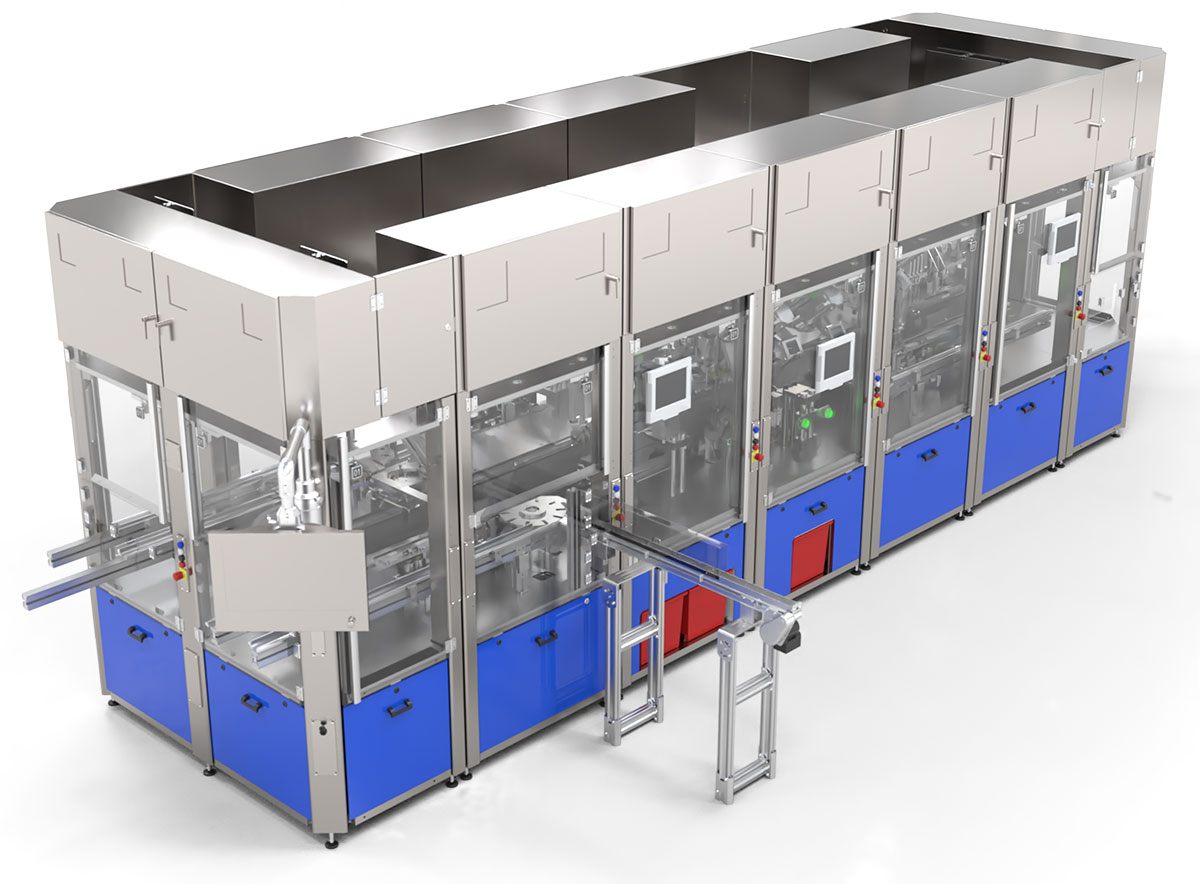

SYMPHONI builds on the best proven assembly technologies – robotics, cam-driven synchronous machines, and power-and-free asynchronous systems – and cleverly combines them for unparalleled performance.

SYMPHONI’s e-Cam is a digital camming system that stands out as the next generation in camming technology, a significant innovation in camming technology.

The e-Cam’s variable machine rate provides significant operational flexibility. This feature enables SYMPHONI to operate at different speeds depending on the requirements of the task at hand.

When focusing on crucial processes that require careful handling of parts, the e-Cam offers both precision and peak performance. This ensures that sensitive operations are executed with the highest level of accuracy.

The e-Cam’s variable machine rate provides significant operational flexibility. This feature enables SYMPHONI to operate at different speeds depending on the requirements of the task at hand.

The workhorse of SYMPHONI technology is its RSM Arm. With precise multi-axis motions and robust construction, the SYMPHONI robot perfectly blends speed and power. Moving in the x and z planes at high speeds, it executes operations with startling efficiency.

When equipped with servo-driven end effectors, the SYMPHONI RSM Arm offers advanced handling capabilities:

Unlike general use ‘spider’ robots, the RSM Arm can handle high forces. Its arms have been optimized through finite element analysis for minimum mass and maximum strength. This optimization provides:

Best of all, the RSM Arm is easy to use. Its motions are configured with selectable profiles that are pre-programmed for common assembly tasks, making it user-friendly and efficient for various applications.

Up to two RSM Arms can be pre-packaged in a module. Motion control is local, managed by the module’s embedded control hardware and SYMPHONI software.

Most assembly systems feature pick-and-place stations in which components received from external feed systems are placed onto a pallet and/or assembled to another component.

The SYMPHONI RSM Arm carries out pick-and-place operations with unmatched speed and efficiency.

Coordinated Movements

The SSYMPHONI RSM Arm coordinates its movements with the numerically controlled movements of other components, including:

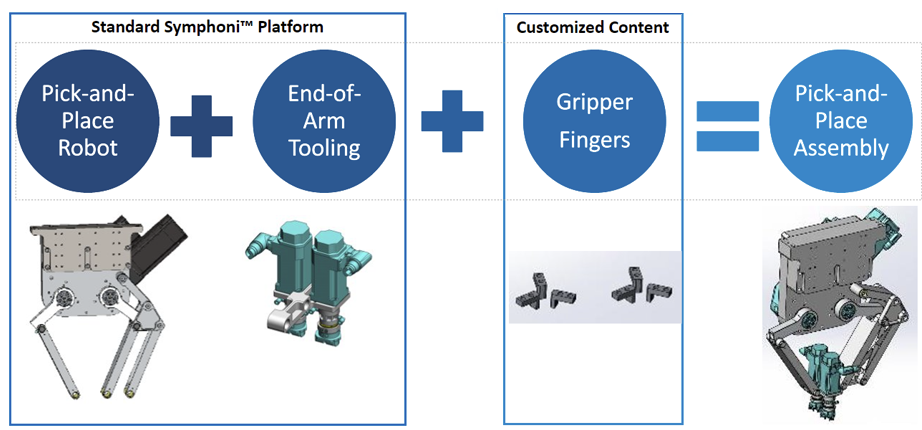

SYMPHONI’ ‘s patent RSM Arms are configured by equipping them with a standard end-of-arm ‘deck’ and part-specific touch tooling, as shown in the image below.

There are numerous decks to choose from, depending on whether:

Although the RSM Arms can be programmed to execute a vast array of customized movements, it can also be quickly configured to follow commonly used motion profiles.

These standard movements are selectable from a library, making programming simple and fast. Specific pick-and-place points can then be dialed in within defined limits in 0.01 mm increments.

Any combination of pressing, orientation, screwing, and assembly.

Pick-and-place vertically.

Disengage part horizontally.

Pick horizontally.

Place vertically.

Pick vertically.

Place vertically

Pick and stop at mid-position to inspect or reject. Unload at second position.

Pick horizontally.

Place vertically. Disengage part horizontally.

The e-Cam is a digital camming system that represents a significant innovation in the field of camming technology. As an ‘electronic camming’ system, it stands out as the next generation of traditional mechanical cams.

Tell me more

Find out how the SYMPHONI assembly platform can work for your application