SYMPHONI™ is a patented, advanced assembly system that outperforms conventional methods by integrating the best features of proven systems.

SYMPHONI is a patented, advanced assembly system that outperforms conventional methods by integrating the best features from different systems.

It combines the digital flexibility of robotics and linear motion conveyance, the high output and cam-driven efficiency of continuous motion and synchronous indexing machines, and the line-balancing power of intelligent shuttles.

End-to-end digital awareness, with status and position of each system device, mapped out in 1-millisecond intervals, verified 200 times per second by self-diagnostics.

< Watch Video | Download Brochure

SYMPHONI uses configurable modules that come with high-performance hardware and standard SYMPHONI e-Cam software, resulting in rapid and efficient operation that reduces delays and respects essential process time.

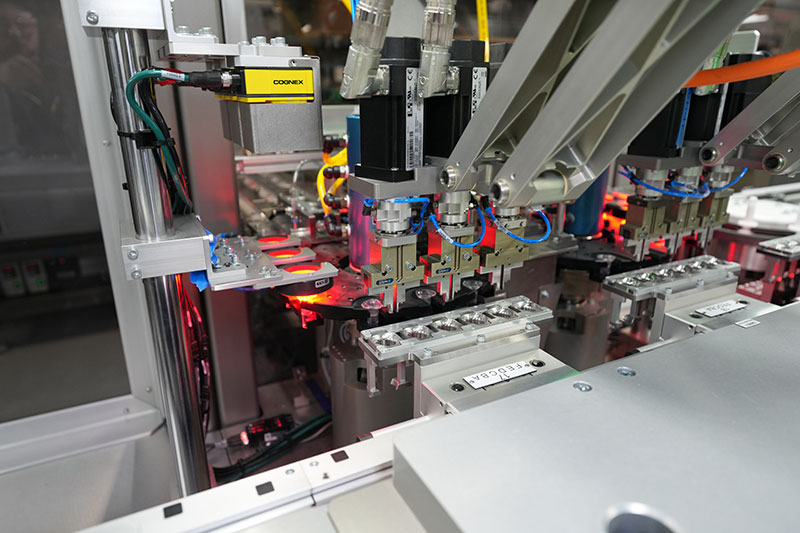

SuperTrak CONVEYANCE™ is just one of SYMPHONI’s engines. Its servo control allows it to transport pallets containing components synchronized with two other SYMPHONI building blocks, the RSM Arm and the RSM Disc.

ATS’ SYMPHONI assembly platform is modular and customizable to meet specific requirements. It is designed to grow to meet consumer demands and deliver one thing—results.

Watch Video >

SYMPHONI technology is unique and remarkably innovative, but not new or unproven. The SYMPHONI platform has evolved over nine years of development and five field-proven generations. Its early innovations resulted in a revolutionary advance in conventional continuous motion assembly. It then expanded to incorporate high-speed robotics and linear motion conveyance. Most recently, we have modularized its construction, making it a standard, scalable, rapidly deployable platform.

SYMPHONI’s versatility allows it to be configured for multi-product use. Rather than sitting idle, it runs constantly, continuing to generate revenue.

SYMPHONI’s synchronous motion, digital flexibility, centralized coordination, and decentralized configuration result in high throughput, optimized cycle times, greater equipment utilization, and gentler parts handling.

SYMPHONI uses servo-driven axes of motion, including conveyance, synchronized and monitored through electronic camming, or e-Cam. The pre-determined control system eliminates sequential processing and ladder logic, reducing non-value-added process time while respecting core processes.

SuperTrak CONVEYANCE™ is a powerful and flexible engine that transports parts within the SYMPHONI system. With over 10,000 units installed globally, SuperTrak is a proven and efficient technology. Its modular design and deep efficiency makes it an integral part of the assembly ecosystem.

SYMPHONI’s RSM Arm is a lightweight and efficient 2-axis arm that uses servo-controlled motion to manipulate products, load parts, and assemble parts on the SuperTrak pallet.

The RSM Disc is a device that functions like a continuous motion dial, but is 90% smaller and free of the inherent mechanical constraints. It is digitally cammed to remove non-value-added cycle time by eliminating traditional escapements and stop/start in-line parts feeding. It transfers parts from an infeed system and synchronizes their motion with the SYMPHONI assembly cell.

The RSM Welder uses the same synchronized motion planning before and after welding, eliminating waste and using fewer welders as a result. When compared to other ultrasonic (US) welding applications limited to <45 cpm, the RSM Welder offered more control during welding, more opportunities for monitoring and testing, and higher weld strength. The SYMPHONI US Welder is capable of rates of 90 ppm per head, and proven in a 410 ppm platform solution – a rate 192% faster than the US weld market leader.

Tell me more

Find out how the SYMPHONI assembly platform can work for your application