SYMPHONI™ machines are multi-purpose assets; they adapt quickly from one product to another. They keep running when dedicated machines sit still; if there are no orders for Product A, it can change to run Product B, or C, or D.

Drawing upon a broad technical base and seasoned experience in multiple markets, our experts collaborate with you using a disciplined data-driven approach. Using standard SYMPHONI cells at our Innovation Center, production processes can be demonstrated through a wide range of speeds with prototype parts.

While completing DFM / DFA activities with confidence, a phased manufacturing strategy can be optimized, and equipment investment determined.

We can show you exactly how we would optimize your future production with SYMPHONI simulations. Because SYMPHONI is a fully digital technology, and all the components, elements and robots have been standardized, we have developed dozens of motion profiles and corresponding simulations. These simulations yield an accurate understanding of the precision versus speed balance.

Simulations show how the same hardware can provide flexibility for potential product changes, product variants, or even different products and processes, perfect for life sciences and other high-risk regulated applications.

Imagine being able to fully describe full-scale production processes at the time you are seeking product approval and, further, being able to use the same equipment for prototyping, clinical trials, early-stage production, and high-volume commercial manufacturing.

Symphoni™ achieves high speeds and delivers versatility without sacrificing gentle handling, critical process time, and precision.

The systems are configurable for a wide range of products, from simple two-piece assemblies to highly complex products having dozens of components and specialized processes. Symphoni systems scale to meet a product’s changing needs as it progresses through its life cycle – from low-volume samples to high-volume production.

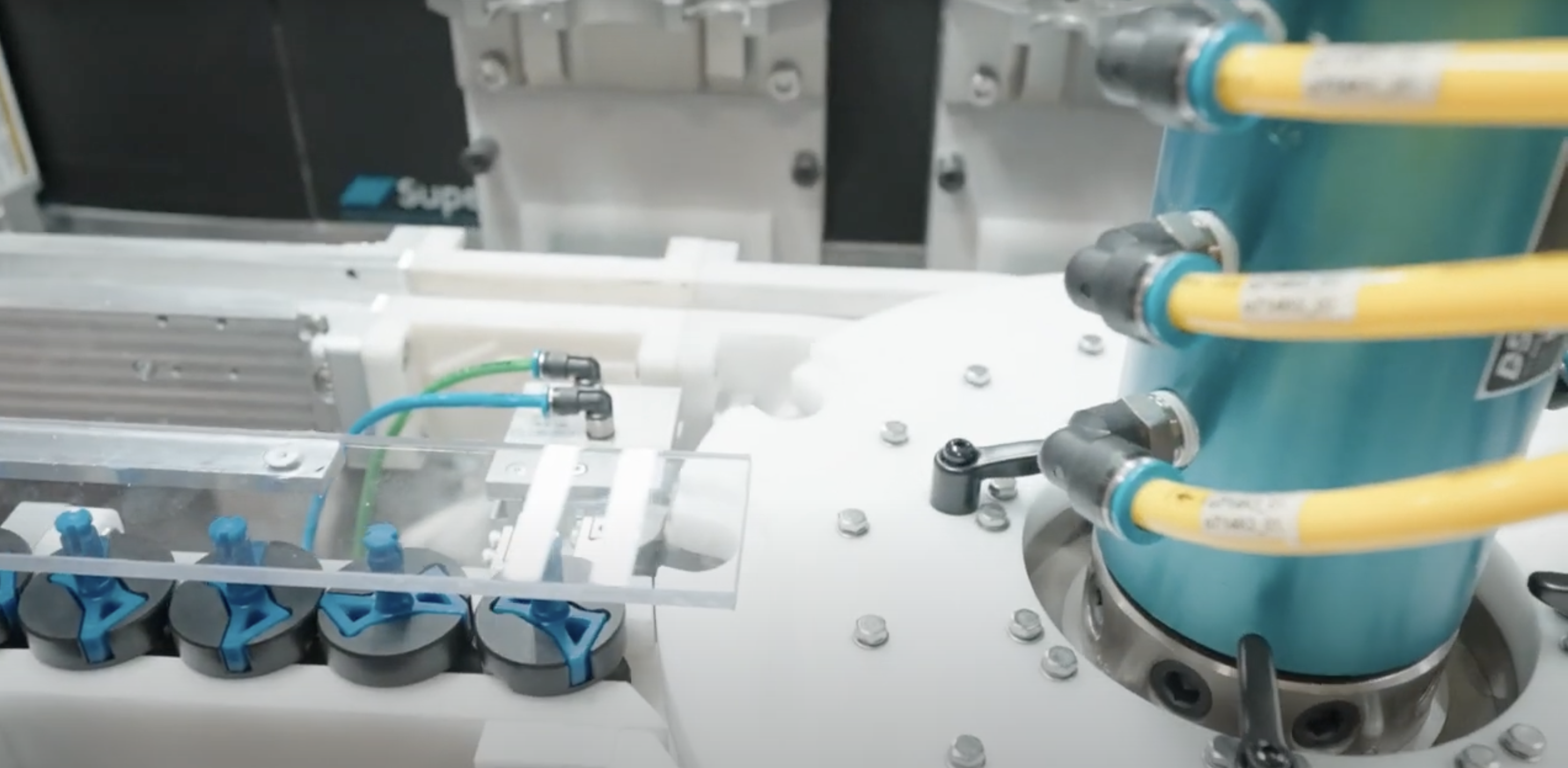

Symphoni’s modular building blocks are designed for plug-and-play configuration, enabling easy retooling, reordering, and repurposing to accommodate product changes.

Its control system directs and synchronizes all functions, eliminating non-value-added movement waste from cycle time, thus ensuring fluid and seamless automation performance.

Digital assembly automation technology featuring an unmatched combination of speed, versatility, and precision in a scalable, modular platform.

Symphoni’s synchronous motion, digital flexibility, centralized coordination, and decentralized configuration result in high throughput, optimized cycle times, greater equipment utilization, and gentler parts handling.

Symphoni is an innovative assembly system that combines the best features of indexing motion, continuous motion, pallets, and robots.

Symphoni’s modular building blocks are designed for plug-and-play configuration, enabling easy retooling, reordering, and repurposing to accommodate product changes.

Its control system directs and synchronizes all functions, eliminating non-value-added movement (waste) from cycle time, thus ensuring fluid and seamless automation performance.

Symphoni is designed to assemble small and discrete components in the medical device and consumer product (CPG) industries. This patented and market-proven solution is configurable, modular, and scalable.

Symphoni’s digital platform is a powerful tool comprised of several core building blocks that work together to deliver exceptional performance. These building blocks are divided into four main categories:

Together, they form a cohesive and efficient system that is greater than the sum of its parts.

Through efficient automation, Symphoni can minimize waste and reduce carbon footprint for the Life Science and Consumer Packaged Goods industries, while producing high-quality goods.

Symphoni’s advanced technologies and innovative processes contribute to more sustainable manufacturing practices, such as reduced energy consumption, optimized resource utilization, and lowered water and land usage.

With the addition of ATS’ Illuminate™ Energy and Efficiency Module, you can measure in real time pneumatic and energy consumption per part/by batch to easily identify and report on carbon footprint.

Responding to the advancement of IIoT and digital manufacturing, ATS has developed technologies that provide a jump-start and significant competitive advantage.

SYMPHONI technology, combined with SuperTrak CONVEYANCE™, results in a fully digital manufacturing platform designed to give manufacturers far greater agility, flexibility and utilization.

Layer on Illuminate™ Manufacturing Intelligence software for complete system diagnostics to pinpoint where to further reduce downtime, realize Overall Equipment Effectiveness (OEE) gains, maximize line throughput, and improve product quality.

< Watch Video | Download Brochure

ATS’ SYMPHONI platform, working with the SuperTrak CONVEYANCE™ system, is leading a revolution in assembly automation where speed, flexibility, and precision are crucial.

Perfect for process development, clinical trials, and low-volume production of medical devices

Accelerate development and time to market, and streamline inventory and the supply chain for Consumer Packaged Goods.

High-volume assembly of CPG; variable speed capable of 10 – 600+ ppm

Autoinjectors, pens

4 – 10 components

Output

up to 400 ppm

Eye dropper bottles and lids

2 – 3 components

Output

up to 320 ppm

Inhalers

Output

up to 320 ppm

High output diagnostic devices

Output

120+ ppm

Tell me more

Find out how the SYMPHONI assembly platform can work for your application