ASK THE EXPERT with Larry Allingham, Key Account Manager at ATS Life Sciences

Is there value in having a high-speed assembly machine if I don’t need high output? Historically, the correct answer has been the obvious one. It wouldn’t have made sense, because…

Is there value in having a high-speed assembly machine if I don’t need high output?

Historically, the correct answer has been the obvious one. It wouldn’t have made sense, because it would have meant buying a more expensive machine than needed. But with today’s technology, the answer isn’t so obvious. Here are some examples of where a high-speed machine can be the better choice for your bottom line, even if you don’t need super high output.

Case 1: Multi-product versatility

A high-speed machine with multi-product versatility can be a far better investment than a dedicated machine whose speed is matched to the needs of a single product. This is because the versatile machine enjoys a higher utilization rate than a dedicated machine, since it can change over to run Product B (or C or D) if there are no orders for Product A. On the other hand, a dedicated machine will sit idle whenever there are no orders for the product it was designed to run. Thus, a versatile machine will generate more revenue over its life than a dedicated machine, yielding an increase in profit that overwhelms the investment premium it requires. The following Figures help illustrate this.

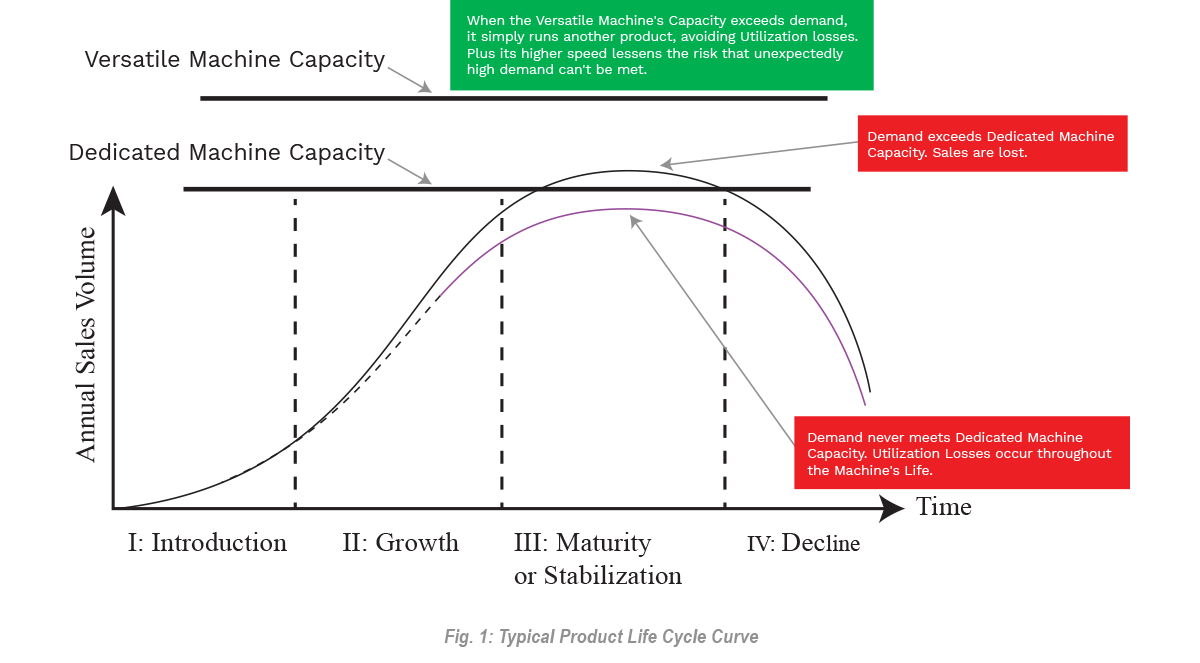

Figure 1 shows a typical product life cycle curve. Initial sales volumes are low, ramping up eventually to meet the projected peak demand. A dedicated machine must be capable of meeting or exceeding this peak, which means it will be underutilized for much of the product’s life. When it’s collecting dust, it’s not making money.

Figure 2 shows the higher profit generated by a versatile machine vs. a dedicated machine. The versatile machine runs more often (i.e., has a higher utilization rate), making more money. The greater the delta in utilization rates between the dedicated machine and the versatile machine, the greater the delta in generated profit.

Case 2: Using high-speed motions to consolidate operations (and thus, cost and space)

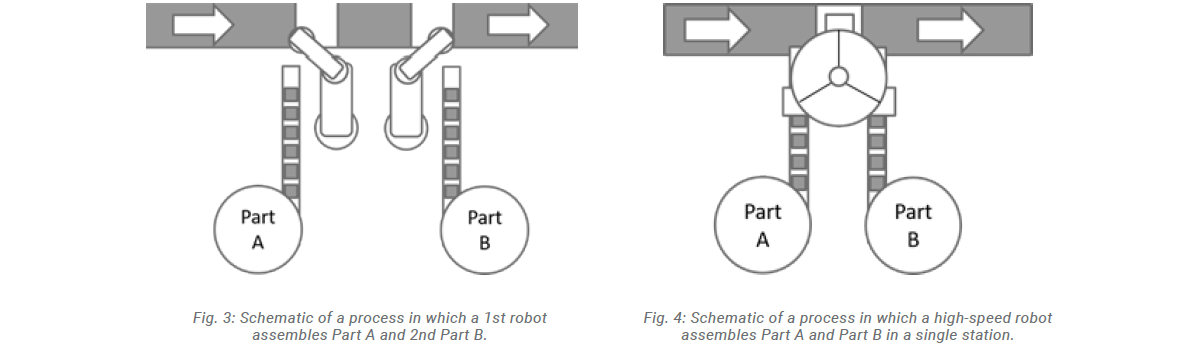

First, let’s recognize that high speed does not necessarily have to mean high rate. Machines with the ability to execute motions at high speeds can often use this ability to consolidate operations. Consider an example. In Figure 3, two robots carry out two successive operations. The first robot picks and places Part A, the second Part B. Both operate within a cycle time needed to produce X parts per minute.

Now let’s consider an alternative, shown in Figure 4. Here we have a single high-speed robot able to pick and place Part A in half the cycle time. It uses the other half of the cycle time to pick and place Part B. The output is the same, X parts per minute. But instead of two robots, we have one – and less cost and floor space.

Case 3: Pre-engineered machines with high-speed capability

Today’s technology permits high-speed machines to come in standard formats, pre-equipped with elements that greatly simplify product-specific customization. Their standard construction translates into lower build costs (and faster lead times). Furthermore, their standardization reduces engineering time, again reducing cost. Bottom line? A standard high-speed machine can be less expensive than customized machine tailored for a lower rate. So even if you don’t need speed, a machine that comes with it can be a better value!

So to summarize the above:

- Versatile high-speed machines can be better values than dedicated lower-speed machines, even if they come at a price premium.

- High speed is an asset than can be profitably exploited even if high rate is not needed.

- Standard, pre-engineered content is a huge asset in a machine, as it minimizes engineering and build costs. If high speed comes along with it– even if you don’t need it – it’s an extra bonus for the future.

Want to learn more?

- For more information about Symphoni and what it can do to meet your assembly needs, please contact us directly at: SymphoniTech@ATSautomation.com

- Sign-Up for our Quarterly Newsletter.

- Connect with us @SymphoniTech on LinkedIn, YouTube, Twitter and Facebook.