SYMPHONI™ is the top-of-the-line configurable assembly automation platform that surpasses the expectations of other modular platforms. It addresses business demands while meeting the technical precision required for efficient production.

SYMPHONI operates with synchronized precision; it is digitally configured and fully flexible. A central ‘master cam’ serves as an electronic line shaft, synchronizing motions system-wide, while individual stations in individual modules remain locally configured and controlled.

Modular mechanical, electrical and software building blocks to expand with your needs

Every SYMPHONI machine is configured from standardized and pre-tested building blocks

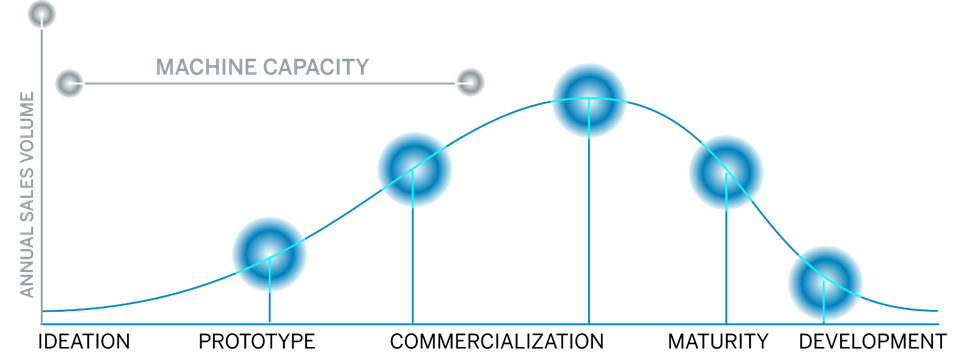

Rapidly reconfigure or retool SYMPHONI to speed up time to market

Modular design allows development of critical processes on production tooling in parallel to design

Tell me more

Find out how the SYMPHONI assembly platform can work for your application