When Faced with a Pandemic, Time is of the Essence!

When syringes needed to be manufactured quickly to meet the distribution demands of life-saving vaccines, Symphoni™ was the technology of choice for the Life Sciences industry. In the early days…

When syringes needed to be manufactured quickly to meet the distribution demands of life-saving vaccines, Symphoni™ was the technology of choice for the Life Sciences industry.

In the early days of COVID-19, the Life Sciences industry prepared to deliver the first rollout of vaccines. These products, including syringes, had to be manufactured at an unprecedented pace, meeting the extreme demands set by governments worldwide. Combined with global supply chain issues, production had to be planned out and scaled up fast. There was no room for error. Lives were at stake.

One such medical device manufacturer reached out to ATS in 2020 (ATS receives a $20M order for COVID-19 vaccine syringe manufacturing line). They wanted to work with a global company that they could trust to deliver automation equipment quickly. Their syringes provided more doses from a single vial than their competitors. Getting every drop out of a needle was critical for the supply of vaccines during the early days of the global rollout.

THE CHALLENGE:

Deliver assembly automation systems FAST to get this innovative syringe to the market as the pandemic continued to rage across the globe.

THE SOLUTION:

Symphoni™! From the first meeting to full production within ten months.

THE RESULTS:

- Multiple Symphoni machines at 360 PPM (3X the rate of traditional assembly solutions).

- 97% MOEE (machine overall equipment effectiveness) at SAT (Site Acceptance Test).

- Reduced floor space > 50% because a high-performance system can replace multiple conventional machines.

- Future-proof assets that can be retooled and/or reconfigured over the equipment’s depreciable life.

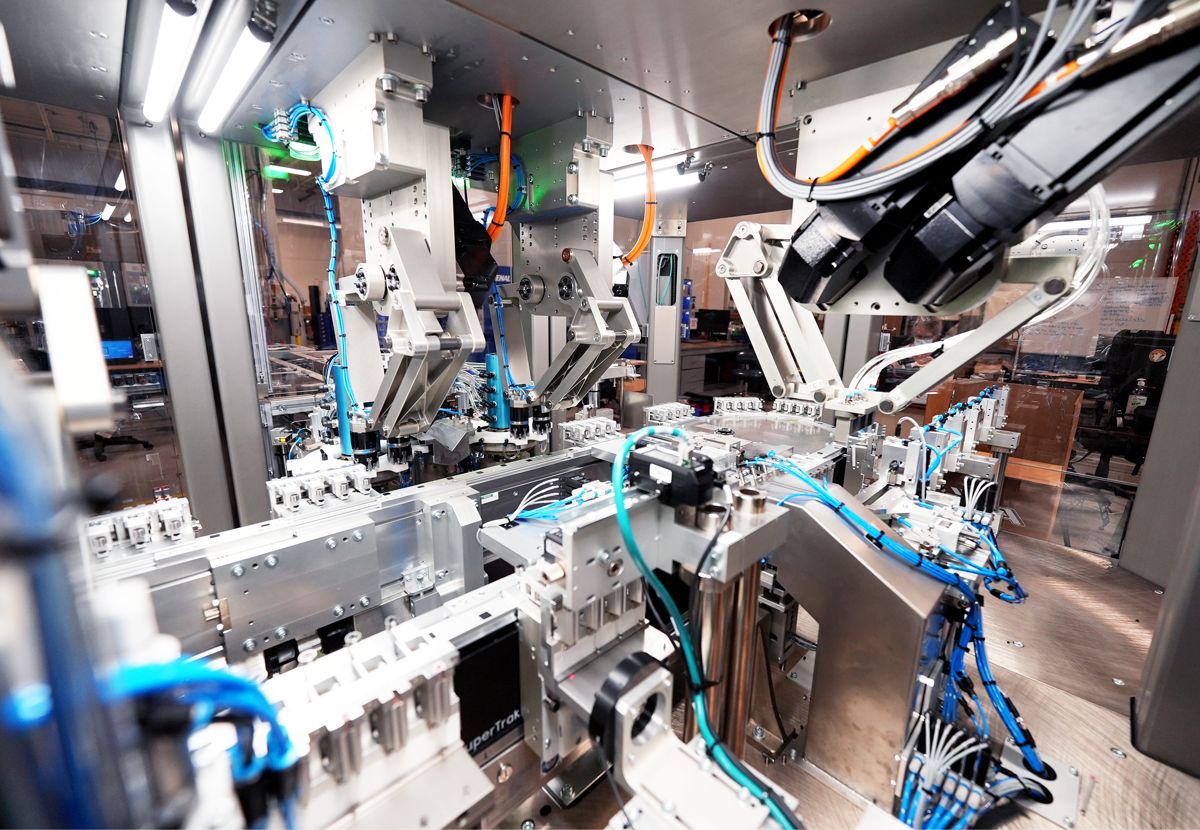

Because time was of the essence, ATS knew our client needed a solution that would significantly reduce delivery time. With over 41 years of building automation equipment, ATS has an extensive portfolio of assembly technologies that could be the answer. However, in this scenario, Symphoni was THE ideal solution for the sub-assemblies feeding into the final production line. Every Symphoni machine is built from standardized, pre-tested, and pre-validated building blocks as well as ATS’s SuperTrak Conveyance™. Similarly, the machine’s software control is configured from Symphoni’s patented OS (Operating Systems) and Illuminate™, a manufacturing intelligence software.

The results have not only met but SURPASSED our client’s expectations. By the time COVID-19 vaccines were ready to be administered worldwide, Symphoni was doing its part—producing syringes at triple the speed without sacrificing precision or quality.

Symphoni’s methodology makes the platform extremely efficient in its operation compared to conventional assembly systems. Symphoni’s patented RSM Technology™ (Rapid Speed Matching) permits Symphoni equipment to achieve high speeds without compromising gentle part handling. In short, the client would have had to purchase multiple slower and inflexible mechanical cam-based machines to achieve the same output as a single electronic cam-based Symphoni.

With its end-to-end synchronous digital control, Symphoni demonstrated how its orchestrated motion produced powerful results at the Site Acceptance Test with an MOEE of 97%!

In Symphoni, our client invested in superior performance machines with smaller footprints that can be scaled up, retooled, and reconfigured to adapt to market changing conditions. Our client now has future-proof assets that will allow them to get their product to the market faster than ten months.

Ten months for new assembly systems with a technology that is three times the speed of any conventional machine sounds like an achievement—and it was. But we aren’t stopping there. Stay tuned!

Want to learn more?

- For more information about Symphoni and what it can do to meet your assembly needs, please contact us directly at: SymphoniTech@ATSautomation.com

- Sign-Up for our Quarterly Newsletter.

- Connect with us @SymphoniTech on LinkedIn, YouTube, Twitter and Facebook.