This is the third instalment of our four-part monthly Symphoni™ blog series. To learn more about Symphoni and how this platform can give you the advantage you need, please register for our Autoinjector Case Study or contact me to receive the link via email.

By Peng-Sang Cau

By Peng-Sang Cau

In this Deconstruct Symphoni series, we’re looking at the building blocks that make a high-speed, high-performance, and uncompromising system like Symphoni™ possible. Our patented Rapid Speed Matching, or RSM Technology®, is at the very heart of this leap forward in assembly automation.

RSM precisely coordinates the movement of Symphoni devices, gearing them together electronically as if they were tied to a mechanical line-shaft. This results in high speeds, gentle parts handling, and a tighter footprint.

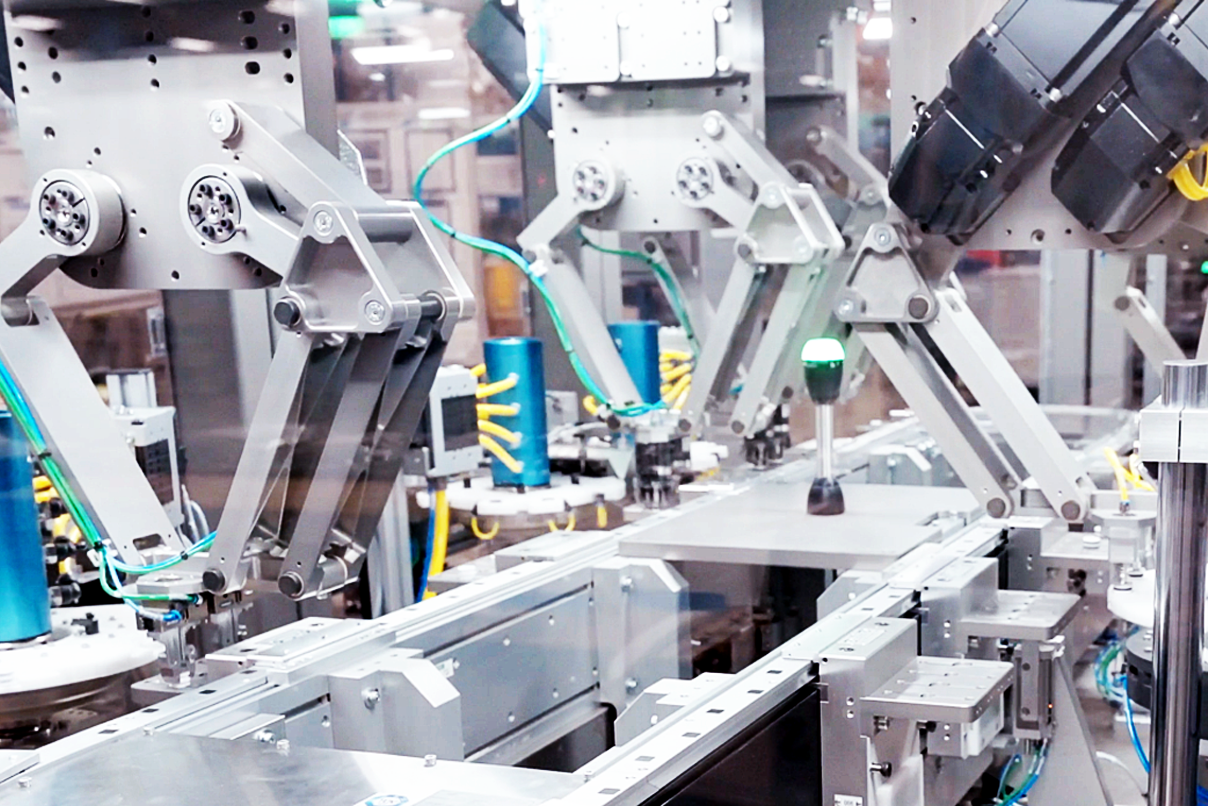

The components that feature our Rapid Speed Matching, or RSM Technology®, may not look that different from conventional custom assembly solutions. The RSM Arm, for example, seems just like any other pick-and-place robot. What’s the difference? The answer is digital. No matter how many arms are in a cell or how many Symphoni systems you operate, each RSM Arm can be programmed with six different motions for six different applications or six different processes. Symphoni doesn’t just perform a single series of motions—it coordinates motion from multiple axes in the most efficient way possible..

Learn more about Symphoni high-speed robotics on our website.

With Symphoni, all axes of motion, including the linear conveyance, are servo-driven, synchronized, controlled, and monitored. Fully coordinated motions are pre-determined events based on a control system that eliminates sequential processing and ladder logic. This results in significant reductions of non-value-added process time, while core processes are respected. This in turn translates to higher output rates, machine efficiency, and quality.

Symphoni’s multi-axis motion coordination allows for adjustments and changes to be made easily, quickly, and concurrently across independent stations. And because the system is constantly being tracked and monitored, there is no need to add secondary sensors or monitoring devices to confirm the completion of discrete events.

What are these two components that feature Rapid Speed Matching, or RSM Technology®?

Symphoni’s RSM Arm is the workhorse of the system. It is a standard and fully tested, lightweight, articulating 2-axis arm that uses servo-controlled motion to efficiently move and manipulate products, load parts from the RSM Disc, and assemble parts on the SuperTrak pallet. In terms of what it does, the RSM Arm is like a conventional pick-and-place robot, capable of numerous standard motion profiles and shapes, featuring high throughput and smooth, reliable operation up to 150 strokes per minute. But when it comes to how it does all this, the RSM Arm is anything but conventional.

The RSM Arm allows Symphoni to go fast where it can and slow where it must. When not handling any parts or product, it uses advanced digital technology to go as fast as possible, thus dramatically reducing non-value-added processes—in other words, it cuts out wasted time. But when the RSM Arm performs core processes, it is precise and controlled, and exerts no additional force on the product.

The RSM Arm is a standard part, allowing it to accept all Symphoni standard decks and requiring minimal maintenance. Because of its simple, elegant, and field-tested design, the system minimizes training needs and labor costs. This means that set-point adjustments and motion profile changes are easy to do through Symphoni’s configuration tools and human-machine interface.

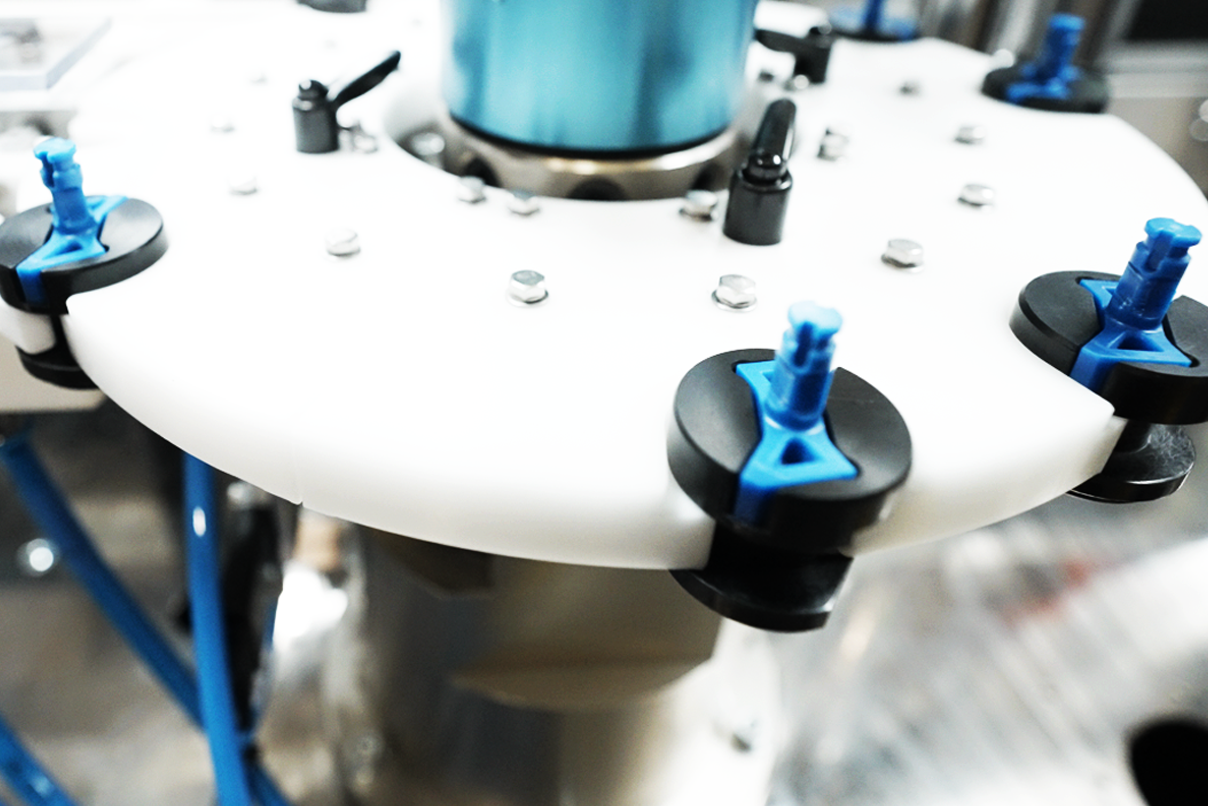

The RSM Disc is a device that functions like continuous motion dials, but it is 90% smaller and free of the inherent mechanical constraints. The RSM Disc is digitally cammed to remove non-value-added cycle time by eliminating traditional escapements and stop / start in-line parts feeding. It transfers parts from an infeed system and synchronizes their motion with the Symphoni assembly cell. This singulation allows each part to take the time it needs to enter the Disc in a gentle, controlled manner, which avoids damage or scratches. Once control has been established, the RSM Disc is then rapidly accelerated to handoff position to maximize rates. Smooth parts feeding yields higher throughput and gentler part handling. It also significantly reduces part jamming.

Furthermore, the RSM Disc is designed for fast changeover with quick release hardware, so no tools are required. This makes it incredibly easy, fast, and simple to swap out the discs for multiple products. The design’s simplicity, paired with its modularity, is why Symphoni is so flexible and easy to scale up.

LS, Vice President

Emerging Markets & Symphoni™

SymphoniTech@ATSautomation.com

Please contact me to discuss a Proof of Concept for assembly needs or to meet with one of our engineers for a deeper dive into your requirements.

Life Sciences, Vice President of Emerging Markets & Symphoni

SymphoniTech@ATSautomation.com

Please contact me to discuss a Proof of Concept or to meet with one of our engineers for a deeper dive into your requirements.

© 2023 ATS Corporation. All Rights Reserved.