This is the second instalment of our four-part monthly Symphoni™ blog series. To learn more about Symphoni and how this platform can give you the advantage you need, please register for our Case Study or contact me to receive the link via email.

By Peng-Sang Cau

By Peng-Sang Cau

I get asked all the time, ‘What is Symphoni?’

I could say that it’s a combination of patented digital technology and a lean methodology of efficiency. Or that it’s an assembly automation platform that delivers the versatility of pallets and robots at continuous motion rates.

But usually, my answer is more straightforward: Symphoni is a digital assembly platform, made up of both hardware and software, that is ideal for assembling consumer-packaged goods (“CPG”), like lotion pumps or lipstick applicators, quickly and precisely. Moreover, because consumer trends are constantly shifting, Symphoni’s inherent flexibility allows the manufacturer to rapidly adapt to market demand.

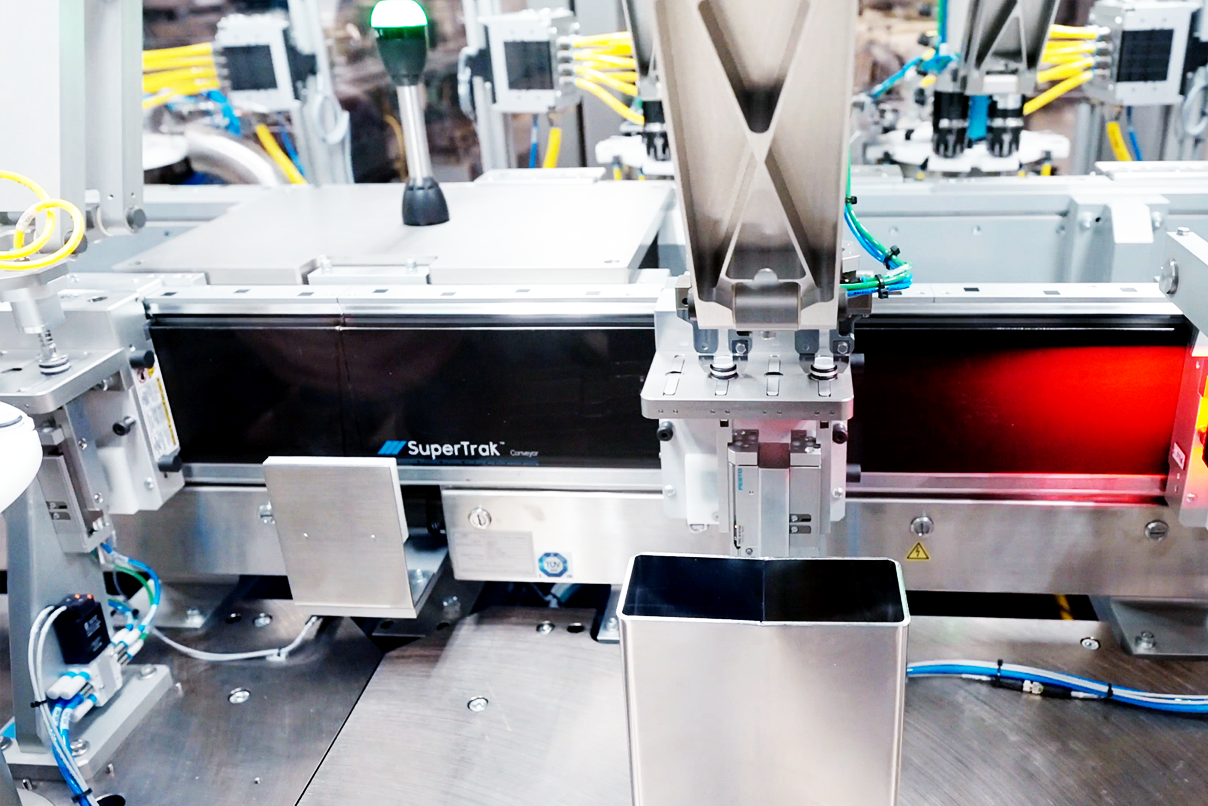

Like Symphoni, SuperTrak expands and adapts as business requirements change.

SuperTrak is one of Symphoni’s core building blocks. It is a linear motion technology that carries parts from one station to the next for processing. SuperTrak is fast, scalable, and redeployable. After 20 years and three generations, one of the first SuperTrak systems ever delivered remains in use today.

Its servo control allows it to synchronize with two other Symphoni building blocks: the RSM Arm and the RSM Disc, both of which will be discussed in-depth next month.

ATS’s Symphoni platform incorporating SuperTrak is a standard solution that can be configured to a whole array of needs. But when you peel back all the layers, it is geared towards reducing total costs of ownership, increasing efficiency and speed without sacrificing quality, and improving time to market.

See Symphoni in Motion on our YouTube Channel @Symphoni

In addition to its speed with gentle parts handling, Symphoni offers three fundamental advantages for CPG manufacturers: flexibility, scalability, and small footprint. Every Symphoni system is configured from standard building blocks that come from our inventory. This reduces automation risk and time to market.

Symphoni is ideal for high-volume products with many complex-shape components and processes like lotion and foaming pumps, but it is also ideal for low-volume, high-value products such as perfume pump sprayers and cosmetics packaging. Conventional machines that use mechanical dials are single-purpose and take up valuable floorspace, and can damage the beautiful finish on products like lipsticks or the cover on perfume pumps.

Symphoni, on the other hand, is a general-purpose, high-speed assembly asset with the flexibility to operate 24/7 by assembling low-volume, high-value products on the same shift with fast tooling change-over or single high-volume. Symphoni is fast but gentle on parts because of its patented E-Cam and Rapid Speed Matching, or RSM Technology®.

Symphoni is inherently scalable, from mechanical building blocks to its servo apps. Manufacturers can start with a single module, called Sonata, to develop and test the production process during R&D, and that same module can be part of the full production system after identical modules are added. Because of the shared functionality between modules, there is no mystery to the process: it’s just like stacking building blocks.

Finally, as a fully digital platform, Symphoni significantly reduces total costs of ownership. Because of its efficiency, Symphoni not only occupies substantially less space, but it also reduces tooling by up to 90%—meaning reduced operating, maintenance, and spares costs.

LS, Vice President

of Emerging Markets & Symphoni™

SymphoniTech@ATSautomation.com

Please contact me to discuss a Proof of Concept for assembly needs or to meet with one of our engineers for a deeper dive into your requirements.

Life Sciences, Vice President of Emerging Markets & Symphoni

SymphoniTech@ATSautomation.com

Please contact me to discuss a Proof of Concept or to meet with one of our engineers for a deeper dive into your requirements.

© 2023 ATS Corporation. All Rights Reserved.